When sourcing products for your beauty brand, the details are what separate a market leader from just another name on the shelf. This is especially true for items like the jade gua sha tool, where perceived quality is everything. But when you’re navigating the world of suppliers, what information truly matters? It’s not about vague promises of “authenticity” or “ancient traditions.” It’s about hard, verifiable production standards. Let’s cut through the noise and focus on the factory-level details that ensure you receive a product that is consistent, high-quality, and worthy of your brand.

Table of Contents

What Sets High-Quality Jade Gua Sha Tools Apart?

Building a successful product line starts with a deep understanding of the materials and manufacturing processes. For a jade gua sha tool , quality isn’t just about the stone’s appearance; it’s about measurable standards that guarantee consistency and performance. These details are what protect your brand’s reputation and ensure customer satisfaction.

Material Standards – Real Jade vs. Alternatives

The first checkpoint is the material itself. The term “jade” is often used loosely, but for a premium product, precision is key. A real jade gua sha tool is typically made from nephrite jade, which is known for its durability and smooth texture, making it ideal for facial massage.

Key Details:

- Genuine Jade Types: Nephrite is the common and practical choice for Gua Sha tools due to its fibrous structure, which makes it tough and less prone to breaking. Jadeite is rarer, more expensive, and often has a more granular, crystalline appearance. Be wary of suppliers who can’t specify which type of jade they use.

- How to Spot Fakes: Watch out for materials like serpentine, aventurine quartz, or even dyed marble being passed off as jade. Unnaturally uniform or overly bright, vibrant colors are red flags for dyeing. A genuine green jade gua sha will have natural variations and subtle imperfections.

- Thickness Standards: A critical but often overlooked detail is the tool’s thickness. We have found the optimal range is 4–6mm. A tool within this range provides a durable gua sha tool for facial massage —it feels substantial in the hand, won’t break easily, and allows for effective pressure without being too sharp or bulky. Anything thinner risks breakage, while anything thicker can be clumsy to use.

Insider Tip: Always ask potential suppliers for retained samples from previous production batches. This allows you to verify their material consistency over time, not just the quality of a single, hand-picked sample.

Color Consistency – ΔE≤3

For any brand owner, consistency is non-negotiable. Imagine a customer buying your natural jade gua sha and then seeing a vastly different shade on display in a store or in a friend’s possession. This erodes trust. In manufacturing, we use a metric called ΔE (Delta E) to measure color difference.

Key Details:

- What is ΔE? ΔE is a standard measurement that quantifies the difference between two colors. A ΔE value of 1.0 is the smallest color difference the human eye can perceive.

- Why It Matters: By holding production to a standard of ΔE≤3, we ensure that there is minimal visible color variation across an entire batch of tools. This means the color consistent jade gua sha you approve in your sample is the same quality your customers will receive.

Insider Tip: Before placing a bulk order, ask your supplier if they can provide a ΔE color difference report. A professional manufacturer like Deyi Gem Co., Ltd. will understand this request and have the equipment to provide this data. This is a clear indicator you are dealing with a factory that takes quality control seriously.

Production Techniques That Impact Quality and Cost

The journey from a raw slab of nephrite to a polished gua sha jade tool involves several key manufacturing steps. The methods used during production directly influence the final product’s quality, consistency, and cost. Understanding these techniques empowers you to make informed decisions and find a balance that fits your brand’s needs.

Polishing – Machine vs. Hand

How a tool is polished determines its final texture and finish. While “hand-polished” might sound artisanal and luxurious, the reality in bulk manufacturing is quite different.

Key Details:

- Machine Polishing: This is the industry standard for reputable factories. Automated polishing processes ensure that every machine polished gua shahas a perfectly uniform surface, smooth edges, and a consistent finish. It is efficient, scalable, and cost-effective, making it ideal for orders of any size.

- Hand Polishing: This method is prone to human error, resulting in inconsistencies in surface smoothness and edge finishing. It is also slow and inefficient, making it unsuitable for producing a consistent product line for a growing brand.

Insider Tip: For any bulk order, you should always confirm the factory uses machine polishing. This simple question helps you gauge their production capabilities and commitment to quality. A supplier pushing “hand-polishing” for large orders may lack the proper equipment for scalable production.

Engraving – Laser vs. Hand Etching

Adding your logo to a product is a crucial step in building brand identity. When it comes to a custom jade gua sha tool , the engraving method impacts both the look and the cost.

Key Details:

- Laser Engraving: This is the superior method for branding. A laser engraved jade tool features a precise, clean, and perfectly replicated logo on every single piece. It is fast, cost-effective, and highly scalable, making it perfect for both small and large batches.

- Hand Etching: While it can have an artistic feel, hand etching is expensive, slow, and impossible to replicate with 100% accuracy across thousands of units. This method is better suited for one-of-a-kind artisanal pieces, not a branded product line.

Insider Tip: For anyone looking to custom gua sha with logo, laser engraving offers the best balance of quality, consistency, and cost. It ensures your branding is professional and uniform across your entire inventory.

Mold Costs and MOQ

Understanding the relationship between mold costs and Minimum Order Quantity (MOQ) is fundamental for any brand owner, especially those looking for private label gua sha tools. This is where production economics directly impacts your bottom line.

Key Details:

- The Math: Creating a custom shape requires a mold, which has a fixed one-time cost. This cost is then amortized across the number of units you order. For example, a $500 mold for a 500-unit order adds $1 to the cost of each tool. However, for a low MOQ gua sha supplier offering a run of just 100 units, that same mold adds $5 to each tool.

- The Trade-off: While a lower MOQ reduces your upfront investment, it increases the per-unit cost. A higher MOQ does the opposite.

Insider Tip: A good manufacturer will be transparent about these costs. Have an open conversation about your budget and desired order quantity. We can often help you find a sweet spot that balances mold costs and unit pricing to fit your business model. This financial transparency is a hallmark of a true production partner.

Red Flags to Watch for When Choosing a Supplier

Your choice of supplier can make or break your product launch. Vetting potential partners is one of the most critical steps in the sourcing process. Knowing what to look for—and what to run from—will save you time, money, and headaches. Here are concrete red flags to consider when you’re learning how to choose a gua sha supplier.

Sampling and Transparency

Samples are your first tangible proof of a factory’s capabilities. A supplier’s attitude toward sampling and transparency speaks volumes about their legitimacy and reliability.

Key Details:

- Refusal to Provide Physical Samples: This is the biggest red flag. If a supplier will only send photos or is hesitant to ship you a physical product, there is a high probability they are a middleman with no control over production. A confident factory is eager to prove its quality.

- Sampling Time >15 Days: A prolonged sampling process (beyond two weeks) often signals internal problems. It could mean the factory has serious capacity constraints, is disorganized, or is outsourcing the sample creation itself.

- Refusal of Video Tours: In today’s global market, a video factory tour is a reasonable and standard request. If a supplier refuses to show you their facility or production line via a live video call, it’s a strong indicator they are not the actual manufacturer.

Insider Tip: Don’t just ask for a sample; test their transparency. Request a live video call to see their polishing machines in action or to watch them pull a thick jade gua sha (4-6mm) from their inventory. A legitimate partner will have nothing to hide.

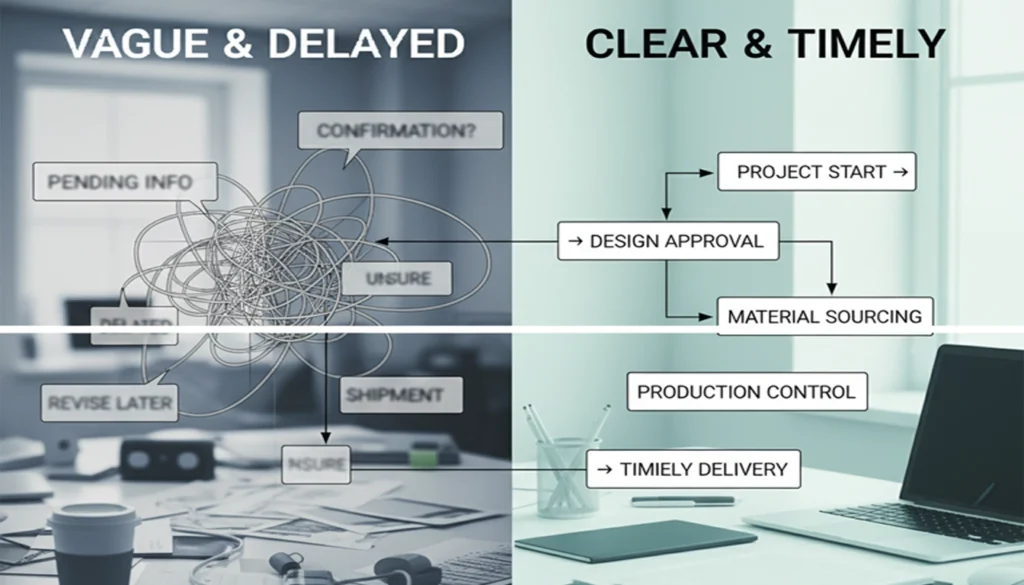

Communication and Responsiveness

Clear, timely, and knowledgeable communication is the backbone of a successful manufacturing partnership. How a supplier communicates before you place an order is a reliable preview of how they’ll communicate once they have your money. These are some of the most critical red flags when buying gua sha tools.

Key Details:

- Vague or Evasive Answers: When you ask specific questions about material sourcing, ΔE values, or polishing methods, you should receive specific answers. If their responses are consistently vague (“we use high-quality jade”), they likely lack the technical expertise you need.

- Inability to Provide Clear Timelines: A professional factory operates on a schedule. They should be able to provide you with a clear, realistic production and shipping timeline. A supplier who can’t commit to a timeline is likely disorganized or overbooked.

Insider Tip: Test their expertise early. Ask a technical question like, “What is your standard tolerance for thickness on a nephrite jade gua sha?” A true expert will answer with confidence and precision. A middleman will likely have to “check with the factory” and get back to you, introducing delays and uncertainty.

Practical Tips for Small-Batch Buyers

Launching a new product line can be daunting, especially for small to medium-sized brands. You need a manufacturing partner who understands your needs and can provide the flexibility and quality required to grow. As a small batch gua sha manufacturer, we know it’s possible to achieve premium quality without committing to a massive inventory.

Customization Without Compromising Quality

For many brands, customization is key to standing out. Are you looking for a personalized jade gua sha ? It’s entirely possible, as long as it’s done correctly.

Key Details:

- Function First: When adding a logo or custom design element, ensure it doesn’t compromise the tool’s functionality. A logo placed on the main massaging edge, for example, could ruin the smooth surface and user experience.

- Experience Matters: Work with a factory that has proven experience with small-batch production. They will understand how to maintain quality control and consistency even on smaller runs, a challenge that factories geared only for mass production often struggle with.

Insider Tip: Always request a pre-production sample that includes your final branding. This allows you to test everything—the material, the finish, the logo placement, and the overall feel—before committing to the full batch.

Balancing Cost and Quality

For any business owner, budget is a primary concern. However, in the premium beauty space, sacrificing quality for a lower price is a false economy. Your customers expect a product that looks and feels luxurious.

Key Details:

- Understand the Costs: As discussed, a lower MOQ often comes with a higher per-unit price. Don’t let this surprise you. A transparent supplier will explain this trade-off clearly.

- Avoid Corner-Cutting: It can be tempting to save a few cents per unit by opting for a thinner stone, a less precise polish, or an unverified material. These small compromises can lead to customer complaints, negative reviews, and damage to your brand’s reputation.

Insider Tip: Focus on long-term value over short-term savings. Investing in a high-quality, consistent jade gua sha tool builds customer loyalty and reinforces your brand’s premium positioning. A happy customer is your most powerful marketing asset.

Final Checklist for Buying Jade Gua Sha Tools

Navigating the sourcing process can be complex, but by focusing on these key technical and logistical points, you can partner with a manufacturer confidently. Use this checklist to vet potential suppliers and ensure you get the quality you’re paying for.

- Verify Material Authenticity: Confirm you are getting genuine nephrite jade with no dyeing. Ask for proof.

- Confirm Thickness Standards: Ensure the tools meet the optimal 4–6mm thickness for durability and performance.

- Request a Color Difference Report: Ask for a ΔE≤3 standard to guarantee color consistency across your order.

- Choose Machine Polishing: Verify the factory uses machine polishing for uniform surfaces on bulk orders.

- Opt for Laser Engraving: Select laser engraving for precise, cost-effective, and scalable branding.

- Negotiate MOQ and Understand Mold Costs: Have a transparent discussion about how order quantity will impact your per-unit price.

- Request Physical Samples and Video Tours: Never commit without seeing a physical product and verifying the factory’s existence.

- Ensure Clear Communication and Timelines: Partner with a supplier who provides clear, expert answers and reliable schedules.

Your Partner in Production

By focusing on these critical production details, you move from being just a buyer to being an informed, empowered brand owner. You can avoid the common pitfalls of sourcing and ensure the jade gua sha tool you sell is a true reflection of your brand’s commitment to quality. This knowledge allows you to build a product that not only meets but exceeds professional standards.

At Deyi Gem Co., Ltd., we operate on these principles of transparency and quality. We aren’t just a supplier; we are a production partner dedicated to helping you build a successful brand. We believe in providing the technical expertise and manufacturing excellence you need to source with confidence.

Ready to create a product built on a foundation of quality? Let’s start a conversation about your project. Ask us the tough questions. We’re here to give you the straightforward answers you need to succeed.

Frequently Asked Questions

How can I tell if a jade gua sha tool is genuine?

Premium tools are typically made from nephrite jade, known for its tough, fibrous structure. Beware of substitutes like serpentine, aventurine quartz, or dyed marble. Genuine jade will have natural variations and slight imperfections. Overly bright or perfectly uniform colors are signs of dyeing. Always request retained samples from past batches to check material consistency.

Why is 4–6mm thickness recommended?

The 4–6mm range provides the best balance of durability, weight, and usability. Tools in this range are less likely to break, feel substantial in the hand, and allow effective pressure without being sharp or bulky.

What does ΔE≤3 mean, and why does color consistency matter?

ΔE is a measure of color difference. A ΔE value of 1.0 is barely visible to the human eye. Keeping production within ΔE≤3 ensures minimal visible variation across a batch, preserving brand consistency and customer trust.

What’s the difference between machine polishing and hand polishing?

Machine polishing ensures consistent surface smoothness and rounded edges across all units, making it ideal for bulk orders. Hand polishing, while artisanal, is slow and prone to inconsistencies, making it unsuitable for scalable brand production.

Should I choose laser engraving or hand etching for my logo?

Laser engraving is fast, precise, and consistent across all units, making it ideal for branded products. Hand etching is better suited for one-of-a-kind pieces, as it’s harder to replicate at scale.